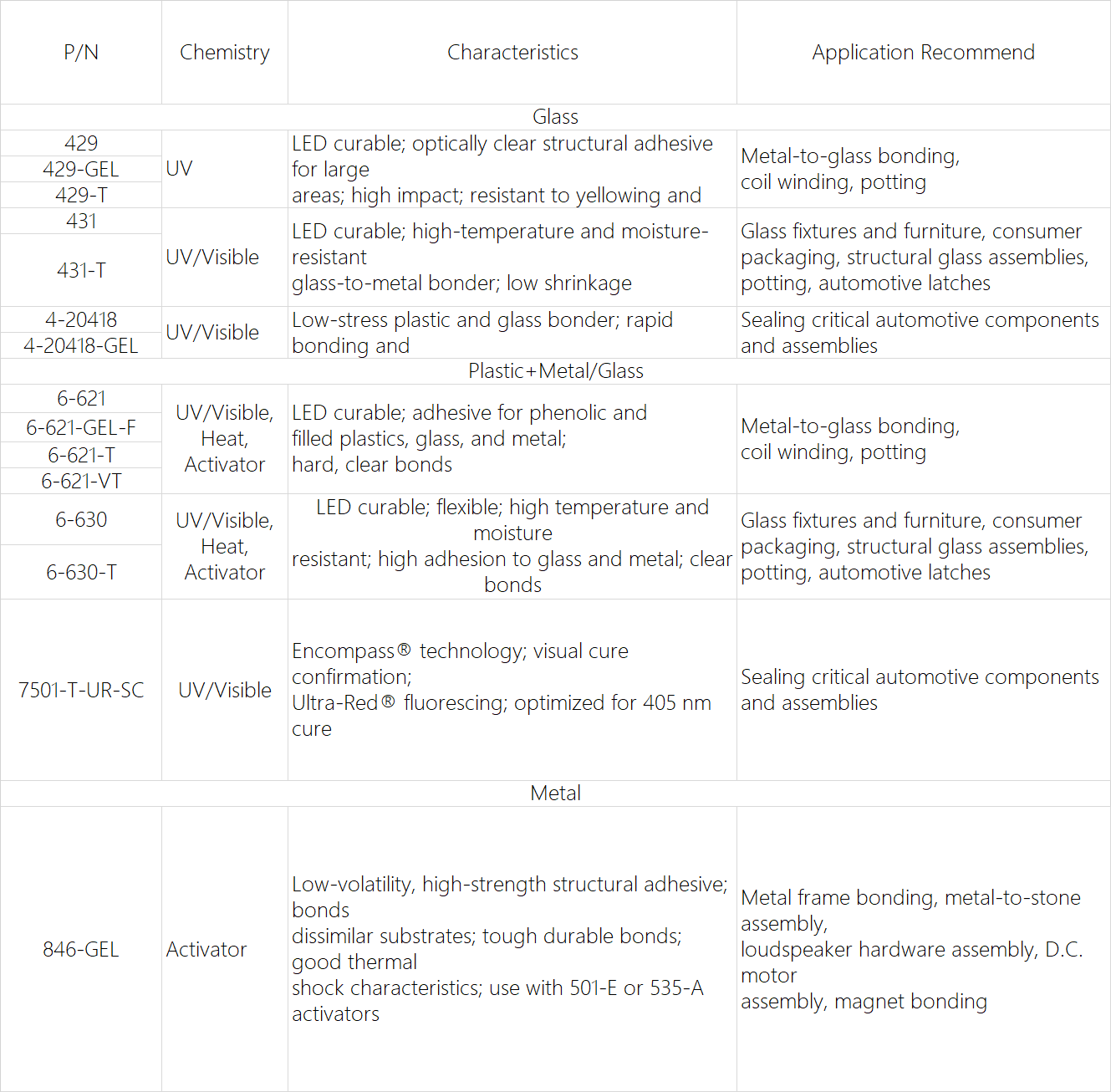

Industrial Metal and Glass

Cure within seconds using UV/Visible light

Multi-Cure - secondary heat cure for shadow areas

Activator cure products available

Acid-free

Non-corrosive

Non-flammable

Suitable for harsh environments

Resistant to high temperatures & moisture

Clear, flexible bonds in some products

Activator-curing metal or structural adhesives brought about the technology revolution known as “cold bonding”. This type of technology shortens the assembly times associated with industrial metal and glass bonding and motor and magnet assembly. The materials cure upon exposure to UV/Visible light, heat (for shadow areas), or activator (for opaque surfaces). The adhesives bond glass, metal, plastic, ceramic, magnets, filled nylon, phenolic plastics, and polyamide, as well as dissimilar substrates. Fast cure time saves space, labor, and regulatory compliance costs making product assembly easier and more efficient for manufacturers.

Typical structural adhesive applications:

- Metal bonding

- Coil winding

- DC motor assembly

- Shallow potting

- Magnet bonding

- Loudspeaker hardware assembly

- Bonding automotive latches

- Consumer packaging

- Glass fixtures & furniture